How 3D Technology Speeds Up Custom Jewelry Production

In the world of custom jewelry, precision, speed, and creativity are essential. As a prominent custom jewelry manufacturer, Sunrise-jewel has adopted innovative technologies to enhance the process of creating custom jewelry. Among these advancements, 3D modeling and 3D printing have played a pivotal role in transforming how custom gold jewelry and custom silver jewelry are designed, prototyped, and produced. These technologies not only boost efficiency but also offer greater customization, allowing designers and customers to explore an unlimited range of possibilities.

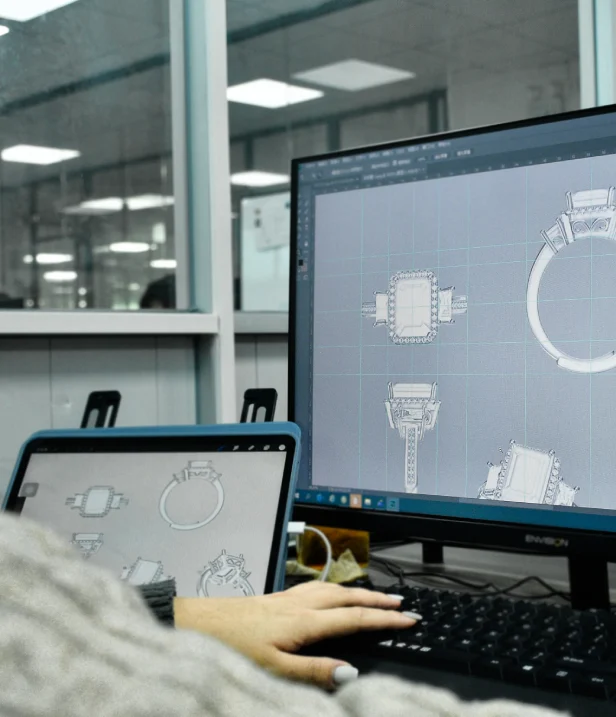

The Role of 3D Modeling in Custom Jewelry Design

At the core of the custom jewelry creation process is 3D modeling. This technology allows designers to create accurate, detailed representations of custom gold jewelry or custom silver jewelry before production begins. With 3D modeling software like Rhino, MatrixGold, and ZBrush, designers can craft intricate designs that would be impossible to achieve through traditional methods. Whether it’s a complex custom gold jewelry piece with delicate details or a sleek, minimalist custom silver jewelry design, 3D modeling provides the flexibility to bring any vision to life.

One of the greatest benefits of 3D modeling is the ability to view the design in three dimensions. Clients can examine their custom jewelry ideas from every angle, providing feedback and making adjustments in real-time. This collaboration between designer and client ensures that the final piece perfectly matches the client’s expectations, making the design process more precise and dynamic.

Additionally, 3D modeling enables designers to work with complex structures and incorporate fine details effortlessly. For example, custom gold jewelry often requires attention to fine features like intricate engravings or gemstone settings. With 3D modeling, these details can be accurately rendered and refined before the piece is even created, ensuring the final product matches the envisioned design perfectly.

The Power of 3D Printing in Custom Jewelry Manufacturing

Once the custom jewelry design is perfected in 3D modeling, the next step is 3D printing. This technology brings an unprecedented level of precision and speed to the jewelry manufacturing process. As a custom jewelry manufacturer, Sunrise-jewel leverages 3D printing to streamline the production of custom silver jewelry and custom gold jewelry. 3D printing allows us to rapidly prototype designs or even produce the finished product directly, cutting out many of the lengthy steps involved in traditional jewelry-making techniques.

The major advantage of 3D printing in custom jewelry production is its ability to create intricate designs with minimal effort. Traditional methods like casting or handcrafting can be labor-intensive and require several steps to achieve the same precision. On the other hand, 3D printing allows designers to print models using materials such as wax or resin, which can then be used to create molds for casting or even to produce the final product directly. This greatly reduces the lead time for custom silver jewelry and custom gold jewelry, making it a go-to choice for clients who need fast turnarounds.

3D printing also speeds up the iteration process. In the creation of custom jewelry, customers often request design adjustments or wish to see multiple variations before making a final decision. With 3D printing, we can quickly produce multiple prototypes and make necessary changes without any significant delays. Whether it’s a minor tweak in the design of a custom gold jewelry pendant or a more intricate adjustment to a custom silver jewelry ring, 3D printing allows us to adapt quickly to the client’s needs.

Combining 3D Modeling and 3D Printing for Seamless Production

The real advantage of 3D modeling and 3D printing lies in their seamless integration. 3D models created using design software are directly converted into 3D print files, ensuring the design is faithfully represented in the final product. This process drastically reduces the chances of errors and discrepancies between the design and the finished product, which is particularly important when working with high-end custom jewelry such as custom gold jewelry and custom silver jewelry.

At Sunrise-jewel, we make sure the transition from 3D modeling to 3D printing is smooth and efficient. Once the design is finalized, the 3D model is printed, usually using wax or resin, which can be used to create a mold for casting. This not only speeds up the prototyping phase but also enhances the accuracy of the final product, ensuring it’s a perfect replica of the original design.

For more complex designs, such as those with multiple gemstones or intricate engravings, the 3D model can be used to create molds that capture every detail. This is especially beneficial for custom gold jewelry and custom silver jewelry, where precision is critical to ensure the final piece meets the client’s expectations. By combining 3D modeling with 3D printing, we can achieve unparalleled precision and speed, making the entire process more efficient and cost-effective for both manufacturers and clients.

Enhancing the Customer Experience

Integrating 3D modeling and 3D printing into the custom jewelry production process significantly enhances the customer experience. For clients looking for custom gold jewelry or custom silver jewelry, these technologies allow them to visualize and refine their designs before production begins. Customers can actively participate in the design process, suggest changes, and make sure every detail is exactly as they wish. This not only improves satisfaction but also builds trust in the manufacturer’s ability to deliver high-quality, customized jewelry.

Additionally, the ability to rapidly produce prototypes and final products means customers no longer have to wait long for their custom jewelry. Whether it’s a bespoke custom silver jewelry engagement ring or a one-of-a-kind custom gold jewelry necklace, 3D modeling and printing allow for faster turnaround times without compromising on quality.

Conclusion

As the demand for custom jewelry continues to rise, so does the need for efficient, precise, and innovative manufacturing techniques. By embracing 3D modeling and 3D printing, Sunrise-jewel is reshaping how custom gold jewelry and custom silver jewelry are designed and manufactured. These technologies offer faster production, more customization, and an enhanced customer experience, making them indispensable tools in modern jewelry making.

By blending artistic skill with state-of-the-art technology, Sunrise-jewel ensures that each piece of custom jewelry is not just a work of art but a true reflection of the client’s vision. With 3D modeling and 3D printing, the possibilities for custom gold jewelry and custom silver jewelry are virtually limitless, making it easier than ever to create unique, high-quality pieces that will last a lifetime.