How To Choosing Metal for Custom Plated Jewelry?

When creating high-end custom jewelry, choosing the right jewelry metal and plated your piece is essential for making sure it looks great and lasts a long time. Whether you’re designing luxury jewelry for your personalized needs, jewelry brand business, wholesale fashion plated jewelry, understanding how the base jewel metal affects the electroplating process is key to achieving the perfect result.

Why Choosing the Right Base Metal is Important

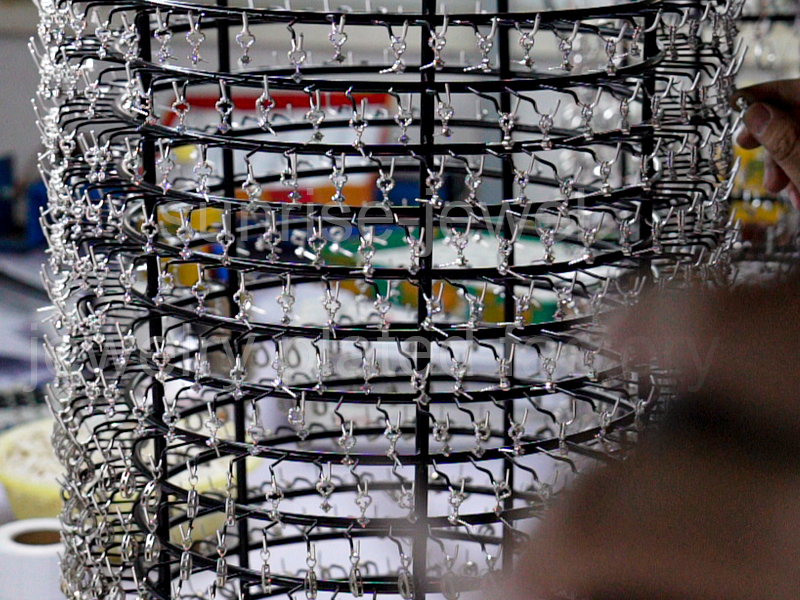

Electroplating is the process of applying a thin layer of metal onto a base material, and this metal layer gives the jewelry its shiny finish. The metal you choose as the base impacts how well the coating sticks and how long it will last. The right base will help the plating stay in place, resist damage, and look beautiful for years.

For anyone new to expanding jewelry business by plated jewelry, a good place to start is Sunrise-jewle who have the plating factory and jewelry produce factory, which can show the whole jewelry making process and more details about plated jewelry and layers.

Common Base Metals for Electroplating

The most common metals used for jewelry bases are copper, stainless steel, and sterling silver. Each of these has its strengths, but also have some different challenges, so let’s look at them in more detail.

Copper: Copper is affordable and easy to work with, making it great for detailed designs. However, copper can tarnish and lose its shine over time, so it usually needs a thicker layer of plating to protect it. It’s good for intricate pieces but requires more care to maintain.

Stainless Steel: Stainless steel is strong, durable, and resistant to rust, making it perfect for pieces that need to last through daily wear. However, it’s harder to plate because its surface doesn’t bond as easily with other metals. This means it requires extra preparation before plating. For more details on how to work with stainless steel in jewelry, The Stainless Steel Industry’s Guide to Jewelry Production can help.

Sterling Silver: Sterling silver is one of the most popular choices for high-end jewelry. It’s smooth and shiny, making it an ideal base for electroplating. Silver works well with different plating options, like gold or rhodium, and it doesn’t tarnish as quickly as copper. This is why sterling silver is often used in fine jewelry, like engagement rings and luxury necklaces.

Why Sunrise-jewel Prefers Sterling Silver

At Sunrise-jewel, we’ve worked with all sorts of metals, and we believe sterling silver is the best choice for most electroplating projects. Here’s why:

Great Surface for Plating: Sterling silver has a smooth surface that makes it ideal for electroplating. The plating sticks well and lasts longer, giving the piece a high-quality finish.

Flexibility: Sterling silver can be plated with a variety of metals, such as gold, rhodium, or even rose gold. This makes it a versatile choice for many designs.

Durability: Sterling silver is naturally resistant to damage, and when it’s plated, the piece is even more durable. At Sunrise-jewel, we also use extra coatings like e-coating or nano-coating to make sure the jewelry stays beautiful longer.

How to Choose the Right Metal for Your Design

When selecting the base metal for your jewelry, think about the design and how the piece will be used. Here are a few tips:

For Detailed Designs: If your piece has lots of tiny details or engravings, copper is a good choice because it’s easy to shape. Just keep in mind that copper tarnishes over time, so it needs a thicker plating layer to protect it.

For Everyday Jewelry: If you’re creating a ring, bracelet, or other piece that will be worn regularly, sterling silver is often the best choice. It’s smooth, durable, and holds plating well.

For Strength: If your jewelry needs to be very strong or resistant to wear and tear, stainless steel is a good option. It’s perfect for men’s jewelry or items like watches. Just remember, it can be trickier to plate, so it requires a bit more work.

How to Ensure Plating Lasts

Electroplating isn’t just about making jewelry shiny—it’s about making sure the coating stays on and looks great over time. Thicker plating layers usually last longer, but they can also cost more. At Sunrise-jewel, we focus on providing high-quality plating that lasts without being overly expensive.

We also recommend adding a protective e-coating or nano-coating. These coatings create an extra layer of protection for the plating, helping it resist damage from scratches or tarnishing.

Conclusion: Small Choices Make a Big Difference

Choosing the right metal for electroplating might seem like a small decision, but it’s a key part of making sure your jewelry is both beautiful and durable. At Sunrise-jewel, we believe sterling silver is the best option for most pieces because of its smooth surface, natural shine, and ability to hold plating well. Whether you’re designing a custom engagement ring or a luxury necklace, we’re here to help you create pieces that stand the test of time.

By focusing on the details, we ensure that each piece of jewelry we create is a lasting work of art that will be cherished for years to come.

More info.: #jewelry factory, #custom silver jewelry, #custom gold jewelry, #custom gold vermeil jewelry, #custom gold plated jewelry…