Many business owners and startups often wonder why manufacturing in China is significantly cheaper compared to other countries such as India, Vietnam, and Thailand. Despite the availability of alternative options, numerous companies continue to choose China as their manufacturing hub. In this discussion, we will explore the reasons behind the cost advantage of producing goods in China.

Lower Labor Costs:

China boasts the largest population in the world, resulting in a substantial labor force. Although labor costs have been gradually increasing, they remain comparatively low when compared to developed nations. The influx of people migrating from rural areas to major cities in search of better employment opportunities ensures a steady supply of labor, which helps keep costs down.

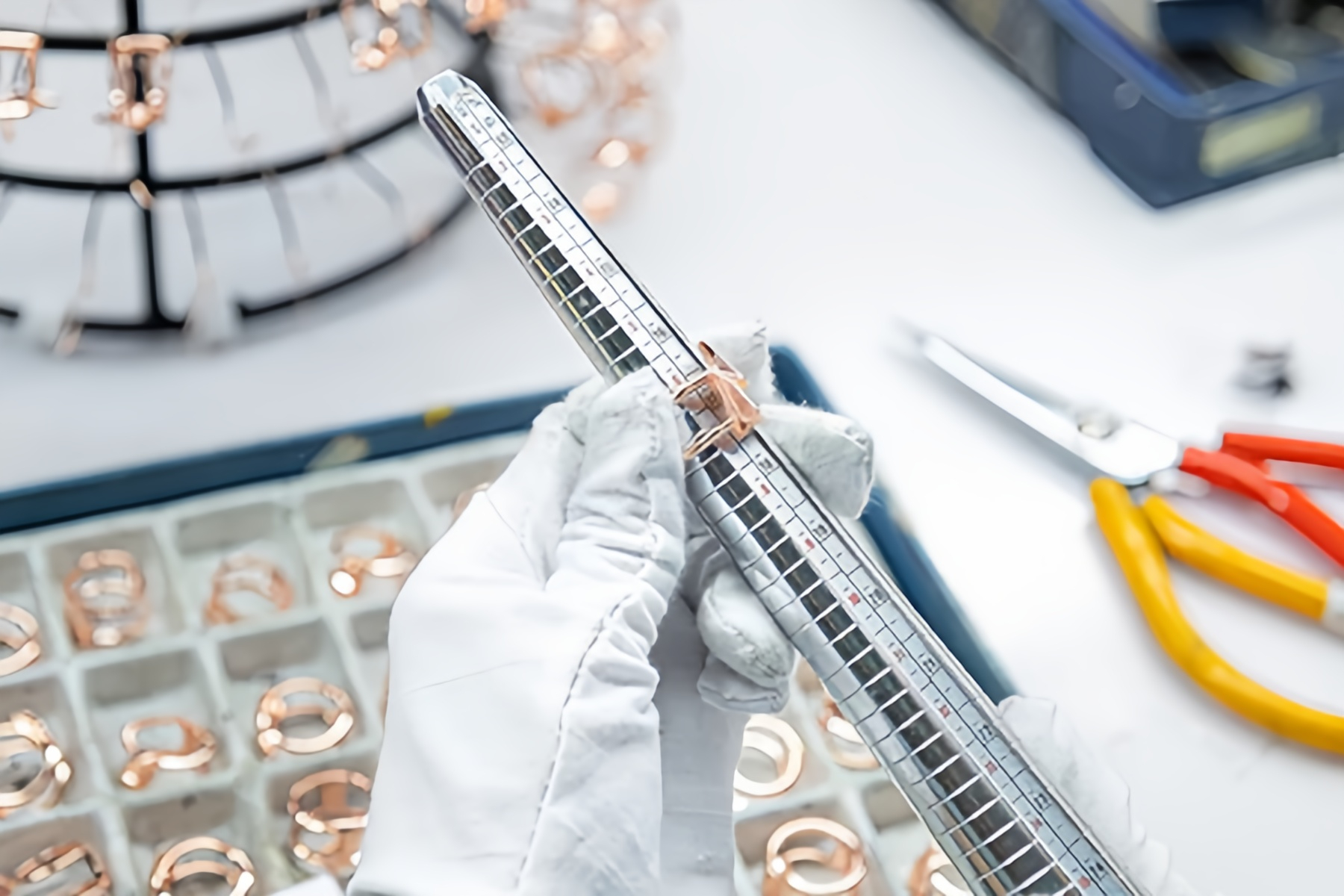

To illustrate, let’s consider the manufacturing of fashion jewelry. In China, the average daily wage for a jewelry maker is below $30, with a slight increase for more intricate designs or specialized skills, amounting to around $40 per day. In comparison, wages in other developing countries may range from $7 to $8, while in the USA, the minimum daily wage could be at least $100.

Large-Scale Production Capabilities:

In today’s rapidly evolving business landscape, competition is fierce. For example, major sport brands like Nike, Adidas, and Under Armour all require footwear manufacturing. By consolidating these substantial orders, Chinese suppliers can engage in large-scale production, which not only becomes feasible but more efficient.

Chinese suppliers benefit from a significant market demand, allowing them to consolidate multiple orders for the same product, resulting in remarkable economies of scale. This factor drives down production costs well below the standards of European and American counterparts.

Affordable Raw Materials:

The affordability of raw materials in China can be attributed to two primary factors. Firstly, China has the capacity to produce a significant portion of its raw materials. Secondly, the high demand for these materials contributes to their lower prices. Additionally, China’s well-developed infrastructure allows for efficient and cost-effective transportation of raw materials.

As an illustration, Damon Lam, a contributor on Quora, explains that China’s infrastructure enables the effective and economical routing of raw materials. Unlike India, China possesses the necessary systems and infrastructure to handle large-scale transportation of raw materials, resulting in minimized costs.

Chinese Government Export Policies:

The Chinese government has implemented policies to promote the export of products worldwide. One such policy is a value-added tax (VAT) system, which only taxes value-added services, making production significantly cheaper compared to other nations.

Conversely, countries like the United States and other developed nations have relatively low import duties for Chinese commodities, further facilitating cost advantages for Chinese manufacturers.

Currency Exchange Rates:

In addition to the jewelry itself, we recognize the importance of impeccable packaging. A dedicated team oversees the packaging process, ensuring that each piece is not only securely packaged but also visually appealing when unveiled by the customer. By paying attention to every detail, we strive to provide a delightful unboxing experience.

Step 6: Last-Minute Inspection Before Shipping

The Chinese Yuan (CNY) is considerably weaker compared to the US dollar (USD), currently at approximately 6.5 times lower. This exchange rate allows companies in China to retain profitability even when pricing their products in US dollars.

While there may be discussions about other countries like India and Vietnam potentially replacing China as the world’s factory, the lack of infrastructure in these countries results in significantly higher costs. Since most products are manufactured for export, a robust nationwide infrastructure plays a vital role in reducing production costs.

Although other countries may catch up in the coming decades, China currently remains the cheapest country for manufacturing products. However, the journey to becoming the next global manufacturing hub is a long one for other nations.